Surface Finishing Preparation

K1 Quality meets the requirements for surfaces which has no decorative needs like wallpaper ect. claddings.

K1 sruface quality process includes the following steps:

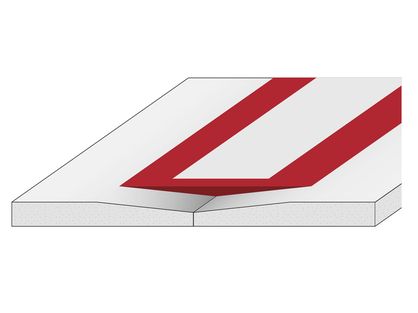

- Placing joint tapes,

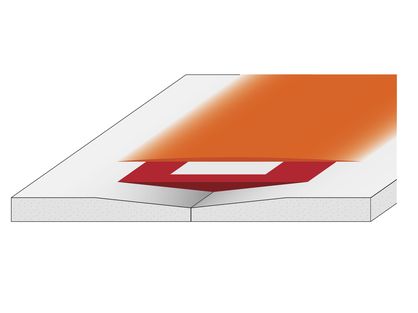

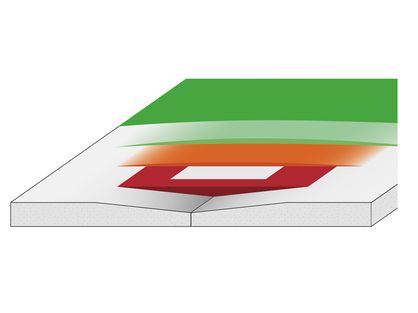

- Filling joints with plaster,

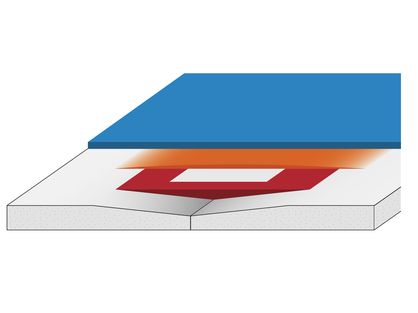

- Covering screw heads.

Extra surface material has to be removed. Corner profiles should be places on the corners. On multiple gypsum board applications, the first layer board's joints should be filled but there's no need to cover the screw heads.

On tile, ceramic ect. cladding applications, this prosedure will be enough. Plaster overflow should be avoided.